The Evolution of knit factories: From Traditional to Modern Techniques

Knit factories have come a long way since their inception, evolving from traditional techniques to modern methods. These factories have played a significant role in the textile industry, producing a wide range of knitted products that we use in our daily lives. In this article, we will explore the evolution of knit factories and how they have adapted to meet the demands of the modern world. Traditionally, knit factories were small-scale operations, often run by families or small communities. These factories relied on manual labor and basic knitting machines to produce their goods. Skilled artisans would meticulously knit each piece by hand, ensuring the highest quality and attention to detail. While this method was time-consuming and labor-intensive, it allowed for a level of craftsmanship that is hard to replicate with modern techniques. As technology advanced, so did the techniques used in knit factories. The introduction of mechanical knitting machines revolutionized the industry, allowing for faster and more efficient production. These machines were capable of knitting multiple stitches simultaneously, significantly increasing productivity. This shift from manual labor to mechanization marked a turning point in the evolution of knit factories.

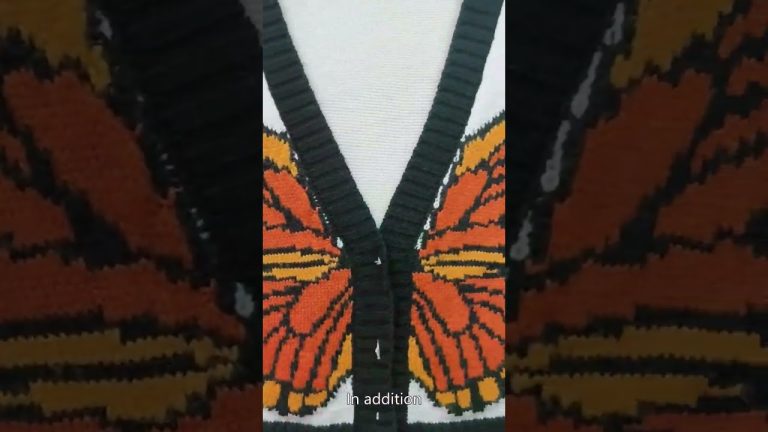

With the advent of computer technology, knit factories entered a new era. Computerized knitting machines became the norm, enabling precise control over stitch patterns and designs. These machines could be programmed to create intricate patterns and complex designs that were previously impossible to achieve. This level of automation not only increased productivity but also opened up new possibilities for creativity and innovation in the industry.

In addition to technological advancements, knit factories have also embraced sustainable practices in recent years. With growing concerns about the environmental impact of the textile industry, many factories have adopted eco-friendly production methods. This includes using organic and recycled materials, reducing waste, and implementing energy-efficient processes. By prioritizing sustainability, knit factories are not only meeting the demands of the modern consumer but also contributing to a greener future.

The evolution of knit factories has also been influenced by changing consumer preferences. In today’s fast-paced world, consumers expect products to be readily available and customizable to their individual needs. To meet these demands, knit factories have implemented just-in-time manufacturing and made-to-order production models. This allows for faster turnaround times and reduces the need for excess inventory. By embracing these modern techniques, knit factories can cater to the ever-changing demands of the market.

Furthermore, the rise of e-commerce has had a profound impact on knit factories. With online shopping becoming increasingly popular, factories have had to adapt to meet the demands of online retailers. This includes streamlining production processes, improving supply chain management, and ensuring timely delivery of products. The ability to quickly respond to online orders has become crucial for the success of knit factories in the digital age.

With the advent of computer technology, knit factories entered a new era. Computerized knitting machines became the norm, enabling precise control over stitch patterns and designs. These machines could be programmed to create intricate patterns and complex designs that were previously impossible to achieve. This level of automation not only increased productivity but also opened up new possibilities for creativity and innovation in the industry.

In addition to technological advancements, knit factories have also embraced sustainable practices in recent years. With growing concerns about the environmental impact of the textile industry, many factories have adopted eco-friendly production methods. This includes using organic and recycled materials, reducing waste, and implementing energy-efficient processes. By prioritizing sustainability, knit factories are not only meeting the demands of the modern consumer but also contributing to a greener future.

The evolution of knit factories has also been influenced by changing consumer preferences. In today’s fast-paced world, consumers expect products to be readily available and customizable to their individual needs. To meet these demands, knit factories have implemented just-in-time manufacturing and made-to-order production models. This allows for faster turnaround times and reduces the need for excess inventory. By embracing these modern techniques, knit factories can cater to the ever-changing demands of the market.

Furthermore, the rise of e-commerce has had a profound impact on knit factories. With online shopping becoming increasingly popular, factories have had to adapt to meet the demands of online retailers. This includes streamlining production processes, improving supply chain management, and ensuring timely delivery of products. The ability to quickly respond to online orders has become crucial for the success of knit factories in the digital age.

| Girls’ sweater | Sweater for boys |

| Wool fabric | All-cotton fabric |