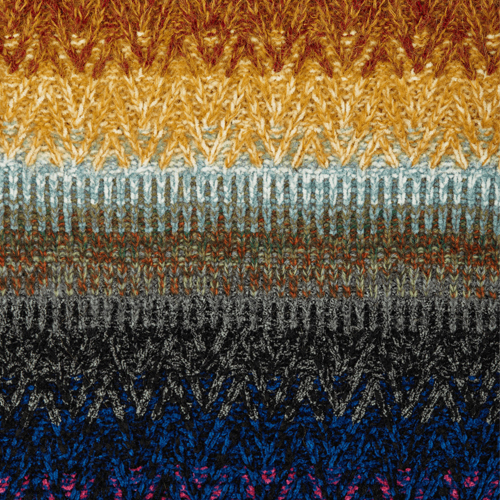

The factory focuses on the production of sweaters. In order to ensure the quality and production stability

About 3200 square meters of factory fabrics are purchased, and there are complete supporting facilities for long-term staff training and production equipment. Domestic and external sales

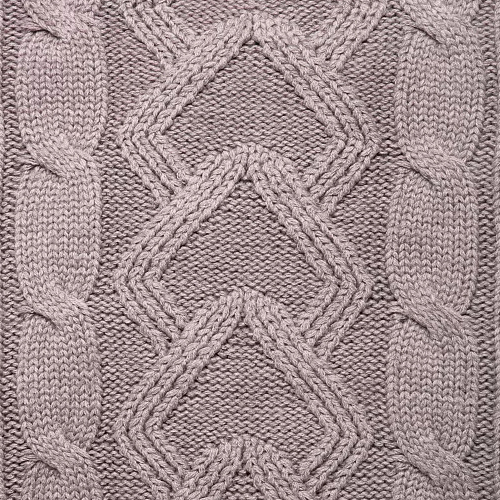

A single customer can receive orders. It mainly produces sweaters with 14 needles (fine needles) to 3 needles (thick needles) for women’s clothing, men’s clothing and children’s clothing.

The annual output is 2 million pieces, and the main export products are domestic, Japan, South Korea, the United States, Europe and other countries

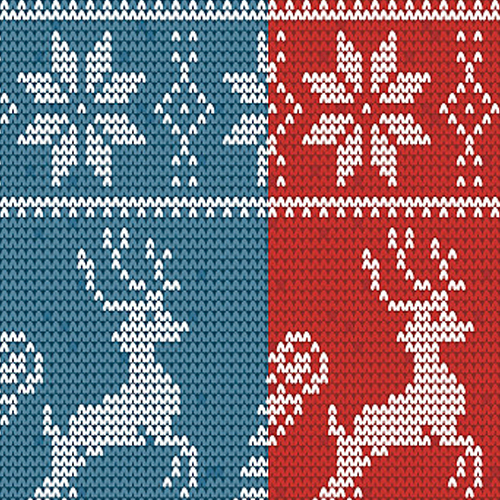

Our equipment advantage: there are 40 STOLLQ flat knitting machines imported from Germany (which can be used to make multi color jacquard and

Wool hanging process, stable needle movement), 300 domestic ordinary flat knitting machines (including cooperative processing plants), 100 disc sewing machines

(including the cooperative processing plant), with its own water washing workshop and 20 permanent positions. There are 6 cooperative factories for embroidery and printing

Complete production links

2 master painters (10 years’ experience), 2 master operators (10 years’ experience), and 1 water washer (10 years’ experience

Inspection), sewing pick, finishing, ironing master (20 years of experience), 50 sewing pick employees (capable of sewing quality goods). stay

In terms of quality assurance, film inspection – seam inspection – finishing (preliminary inspection – recheck – general inspection) and other links are set up, and each sample garment is striped

Code, managed through ERP production system. Ensure that each link of the process is found in time to ensure the quality and delivery time.

There are more than 2000 wool shops within 2km around our factory. We have a wide variety of wool materials and convenient communication for proofing. We look forward to

Be able to establish long-term cooperative production relationship with customers and become the quality supplier of customers!

Our company has 20 years of development history, is a focus on sweater OEM processing enterprises.

The factory focuses on the production of sweaters. In order to ensure the quality and production stability

About 3200 square meters of factory fabrics are purchased, and there are complete supporting facilities for long-term staff training and production equipment. Domestic and external sales

A single customer can receive orders. It mainly produces sweaters with 14 needles (fine needles) to 3 needles (thick needles) for women’s clothing, men’s clothing and children’s clothing.

The annual output is 2 million pieces, and the main export products are domestic, Japan, South Korea, the United States, Europe and other countries

Our equipment advantage: there are 40 STOLLQ flat knitting machines imported from Germany (which can be used to make multi color jacquard and

Wool hanging process, stable needle movement), 300 domestic ordinary flat knitting machines (including cooperative processing plants), 100 disc sewing machines

(including the cooperative processing plant), with its own water washing workshop and 20 permanent positions. There are 6 cooperative factories for embroidery and printing

Complete production links

Our staff and other advantages: 5 salesmen with 5 years of order receiving experience, 3 teachers with 20 years of experience

2 master painters (10 years’ experience), 2 master operators (10 years’ experience), and 1 water washer (10 years’ experience

Inspection), sewing pick, finishing, ironing master (20 years of experience), 50 sewing pick employees (capable of sewing quality goods). stay

In terms of quality assurance, film inspection – seam inspection – finishing (preliminary inspection – recheck – general inspection) and other links are set up, and each sample garment is striped

Code, managed through ERP production system. Ensure that each link of the process is found in time to ensure the quality and delivery time.

There are more than 2000 wool shops within 2km around our factory. We have a wide variety of wool materials and convenient communication for proofing. We look forward to

Be able to establish long-term cooperative production relationship with customers and become the quality supplier of customers!

The factory is located in the largest wool trade market in China (there are tens of thousands of wool shops around to provide various fabrics)