The Evolution of knit industrial Factories: A Look into the Past, Present, and Future

Knit industrial factories have played a significant role in the fashion industry for decades. These factories are responsible for producing a wide range of knitwear, from sweaters to scarves to socks. Over the years, these factories have evolved in many ways, adapting to changes in technology, consumer preferences, and environmental concerns.

In the past, knit industrial factories were often large, noisy, and bustling with activity. Workers would operate heavy machinery to knit fabrics, often working long hours in less than ideal conditions. However, as technology advanced, these factories began to modernize. Automated machines were introduced, making the production process more efficient and reducing the need for manual labor.

One of the most well-known knit industrial factories is the gap sweater factory. The Gap has been a staple in the fashion industry for years, known for its high-quality knitwear. The Gap sweater factory has been at the forefront of innovation, constantly seeking ways to improve its production processes and reduce its environmental impact.

Today, knit industrial factories are more sustainable and environmentally friendly than ever before. Many factories have implemented eco-friendly practices, such as using recycled materials and reducing waste. The Gap sweater factory, for example, has partnered with sustainable suppliers to source materials that are both high-quality and environmentally friendly.

In addition to sustainability, knit industrial factories have also embraced technology in new and exciting ways. 3D knitting machines have revolutionized the production process, allowing factories to create intricate designs and patterns with ease. These machines are faster and more precise than traditional knitting machines, resulting in higher-quality products.

Looking towards the future, knit industrial factories are poised to continue evolving. With advancements in technology and a growing focus on sustainability, these factories are well-positioned to meet the demands of a changing industry. The Gap sweater factory, for example, is exploring new ways to reduce its carbon footprint and improve its supply chain.

As consumer preferences shift towards more sustainable and ethically produced clothing, knit industrial factories will need to adapt to meet these demands. The Gap sweater factory, along with other factories in the industry, are already taking steps to ensure that their products are produced in a responsible and ethical manner.

In conclusion, knit industrial factories have come a long way since their inception. From the noisy, bustling factories of the past to the modern, sustainable factories of today, these factories have evolved in many ways. The Gap sweater factory is a prime example of this evolution, constantly seeking ways to improve its production processes and reduce its environmental impact. As technology continues to advance and consumer preferences change, knit industrial factories will need to adapt to meet these demands. The future of knit industrial factories is bright, with endless possibilities for innovation and growth.

Behind the Scenes at the Gap Sweater Factory: How Your Favorite Sweaters are Made

Have you ever wondered how your favorite sweaters are made? Behind the scenes at the Gap sweater factory, a team of skilled workers and state-of-the-art machinery come together to create the cozy garments that you love to wear. From selecting the finest materials to meticulously crafting each stitch, every step of the process is carefully executed to ensure the highest quality end product.

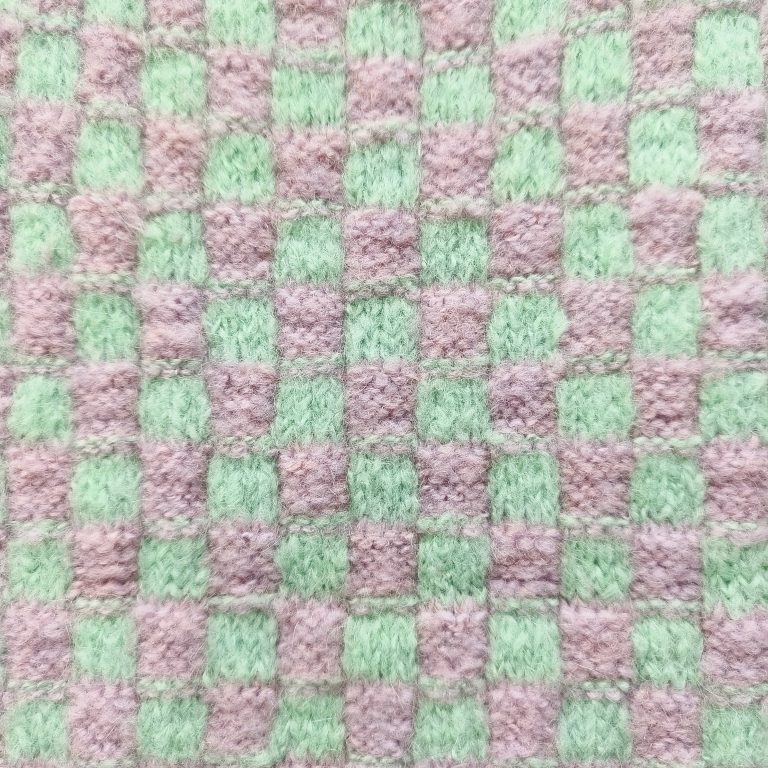

The journey of a sweater begins with the selection of materials. At the Gap factory, only the finest yarns are used to create their signature soft and comfortable sweaters. Whether it’s luxurious cashmere or durable cotton, each material is carefully chosen to ensure that the final product meets the brand’s high standards. Once the materials are selected, they are sent to the knitting machines where the magic begins.

The knitting process is where the sweater truly takes shape. Skilled technicians program the machines to create intricate patterns and designs, carefully monitoring the process to ensure that each stitch is perfect. From classic cable knits to trendy color-block designs, the possibilities are endless when it comes to creating unique and stylish sweaters. As the machines work their magic, the sweaters begin to take shape, with each garment coming to life one stitch at a time.

After the knitting process is complete, the sweaters move on to the finishing stage. Here, any loose threads are trimmed, and the garments are inspected for quality control. Any imperfections are carefully corrected, ensuring that each sweater meets the brand’s high standards before it is sent off to be packaged and shipped to stores around the world.

Behind the scenes at the Gap sweater factory, a team of dedicated workers plays a crucial role in bringing your favorite sweaters to life. From the skilled technicians who operate the knitting machines to the quality control inspectors who ensure that each garment meets the brand’s high standards, every step of the process is essential to creating the high-quality sweaters that Gap is known for.

| men’s cashmere sweater producer | cardigan white manufacturer |

| dress cardigan manufacturer | fleece button sweater maker |

| custom knitted dress Producer | sueter rojo manufacturer |

| pullover crewneck Producer | maglione di natale Producer |

As you slip on your favorite Gap sweater, take a moment to appreciate the craftsmanship and attention to detail that went into creating it. From the selection of materials to the intricate knitting process, every step of the journey is carefully executed to ensure that you are getting a top-quality garment that will keep you warm and stylish for years to come.

So the next time you reach for a cozy sweater to ward off the chill, remember the hard work and dedication that went into creating it. Behind the scenes at the Gap sweater factory, a team of skilled workers and state-of-the-art machinery are working tirelessly to bring you the high-quality garments that you love.