sweater production flow chart

sweaters are a staple in everyone’s wardrobe, especially during the colder months. Whether you prefer a cozy knit cardigan or a classic jumper, the process of producing these garments is intricate and fascinating. In this article, we will take a closer look at the sweater production flow chart and how custom-made knitted cardigans and jumpers are created in a production factory.

The first step in the sweater production process is designing the garment. This involves creating sketches and selecting materials such as yarn, buttons, and zippers. Once the design is finalized, the next step is to create a sample garment to ensure that the design is feasible and meets the desired specifications.

After the sample garment is approved, the production process begins. The first step is to source the materials needed for the sweater, such as yarn and trimmings. These materials are then inspected for quality and consistency before being sent to the production line.

| Sort | Product | Fabric variety | Supply model |

| 1.1 | zip jumper | CAMELI | sweater Firm |

The next step in the production process is knitting the fabric. This is done using specialized knitting machines that can create intricate patterns and designs. Once the fabric is knitted, it is inspected for any defects or inconsistencies before being sent to the cutting department.

In the cutting department, the fabric is cut into pieces according to the pattern of the sweater. This is a crucial step in the production process, as any mistakes in cutting can result in a flawed garment. Once the pieces are cut, they are sorted and bundled together before being sent to the sewing department.

| knitwearampang Maker | mens rhinestone sweater maker |

| zip sweater producer | triko kazak manufacturer |

| down sweater Producer | fashion manufacturers Producer |

| wool sweater for girls manufacturer | men zipper sweater Producer |

In the sewing department, the pieces of fabric are stitched together to create the final garment. This is where the sweater really starts to take shape, as the sleeves, collar, and buttons are all attached to the main body of the sweater. Once the garment is fully assembled, it is inspected for any defects before being sent to the finishing department.

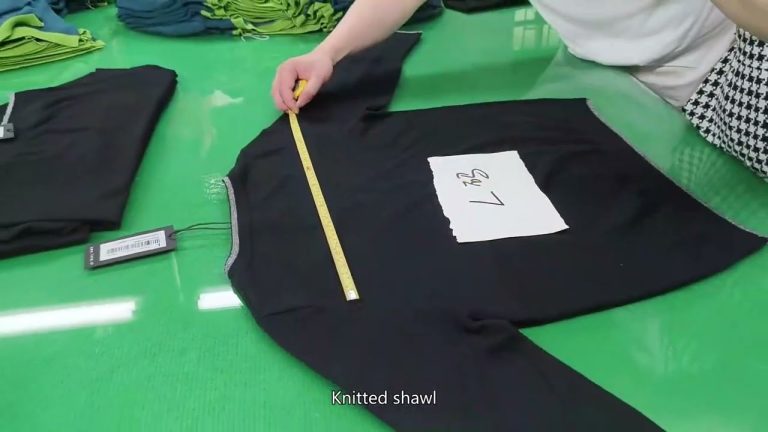

In the finishing department, the sweater is washed, pressed, and inspected one final time before being packaged and shipped to retailers. This is where any loose threads or imperfections are fixed, ensuring that the sweater is of the highest quality before it reaches the customer.

Custom-made knitted cardigans and jumpers are a popular choice for those looking for a unique and personalized garment. In a production factory, custom orders are handled with care and attention to detail. Customers can choose the color, pattern, and style of their sweater, creating a one-of-a-kind garment that is tailored to their preferences.

In conclusion, the sweater production flow chart is a complex process that involves multiple steps and departments working together to create a high-quality garment. From designing the sweater to knitting the fabric, cutting and sewing the pieces, and finishing the garment, each step is crucial in ensuring that the final product meets the desired specifications. Custom-made knitted cardigans and jumpers add an extra layer of personalization to the production process, allowing customers to create a unique garment that reflects their individual style.