The Process of sweater production

sweaters are a staple in many people’s wardrobes, providing warmth and style during the colder months. But have you ever wondered how these cozy garments are made? The process of sweater production is a fascinating one that involves a combination of skilled craftsmanship and modern technology.

| knitwear set manufacturer | nurse sweater producer |

| women maglione Maker | sweater chompas manufacturer |

At the heart of sweater production is the industrial factory where the magic happens. These factories are equipped with state-of-the-art machinery that can knit, dye, and finish sweaters with precision and efficiency. The process begins with the design phase, where designers create patterns and select materials for the sweaters. Once the design is finalized, it is sent to the factory floor where the production process begins.

One of the key steps in sweater production is knitting. Knitting machines are used to create the fabric that will eventually become a sweater. These machines can produce a wide variety of knit patterns, from simple stitches to intricate designs. The type of knit used will depend on the style and function of the sweater being produced.

After the fabric is knit, it is dyed to achieve the desired color. Dyeing is a crucial step in the production process, as it can greatly impact the final look of the sweater. Once the fabric is dyed, it is washed and dried to ensure that the color is set and the fabric is ready for the next step.

| Encoding | Product Name | Fabric variety | Supply model |

| 1-1 | cardigan knitwear | SPUNRAYON | sweater personalization |

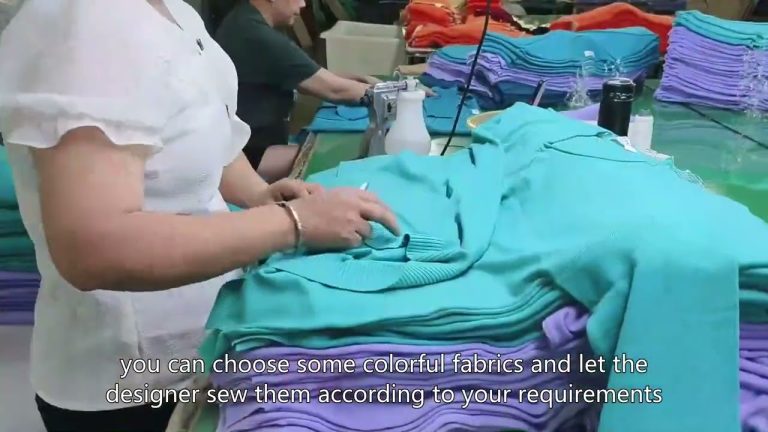

Once the fabric is prepared, it is cut and sewn together to create the final sweater. Skilled workers use sewing machines to stitch the pieces of fabric together, creating the body, sleeves, and neckline of the sweater. This step requires precision and attention to detail to ensure that the sweater is well-constructed and fits properly.

After the sweater is sewn together, it is finished with details such as ribbing, cuffs, and buttons. These finishing touches add style and functionality to the sweater, making it ready to be worn. Once the sweater is complete, it is inspected for quality control to ensure that it meets the factory’s standards.

In addition to mass-produced sweaters, many factories also offer customized sweater production. This allows customers to create their own unique sweaters with personalized designs, colors, and details. Customized sweaters are a popular choice for businesses, sports teams, and organizations looking to create branded merchandise or uniforms.

Overall, the process of sweater production is a complex and intricate one that requires a combination of skill, technology, and attention to detail. From the design phase to the finishing touches, each step in the production process plays a crucial role in creating high-quality sweaters that are both stylish and functional.

Whether you prefer a classic cable-knit sweater or a trendy hoodie, the production process ensures that each garment is made with care and precision. So next time you slip on your favorite sweater, take a moment to appreciate the craftsmanship and hard work that went into creating it.