Exploring the Manufacturing Process of Women’s sweaters in a Factory Complex

Women’s sweaters are a staple in many wardrobes, providing warmth and style during the colder months. Have you ever wondered how these cozy garments are made? Let’s take a closer look at the manufacturing process of women’s sweaters in a factory complex.

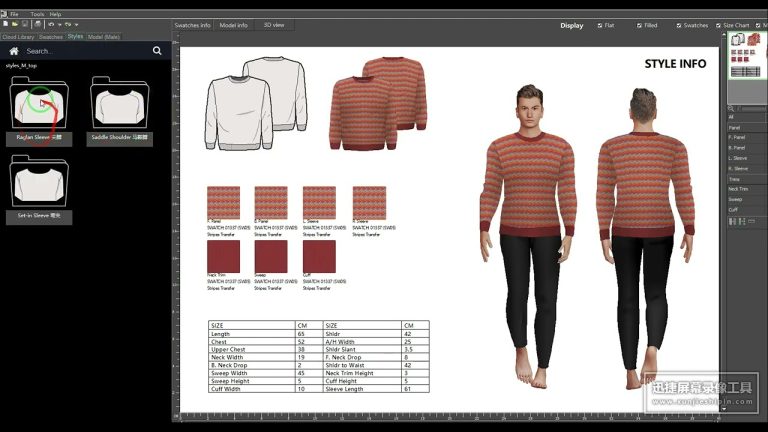

In a factory complex dedicated to producing women’s sweaters, the process begins with the design phase. Designers work tirelessly to create unique and fashionable sweater designs that will appeal to consumers. Once the designs are finalized, they are sent to the production team to bring them to life.

The next step in the manufacturing process is sourcing materials. High-quality yarns are essential for creating durable and comfortable sweaters. The factory complex works with suppliers to ensure that they have access to the best materials available. Once the materials are sourced, they are carefully inspected for quality before being used in production.

With materials in hand, the production team can begin the manufacturing process. Skilled workers operate knitting machines to create the fabric panels that will eventually be sewn together to form the sweater. Each panel is carefully inspected for any defects before moving on to the next step.

| Nr. | Product classification | Fabric category | Supply model |

| 1-1 | kaschmir pullover | POLYNOSIC | sweater Personalized modification |

After the fabric panels are knit, they are sent to the sewing department. Here, skilled seamstresses work diligently to sew the panels together, following the design specifications provided by the designers. This step requires precision and attention to detail to ensure that each sweater is constructed correctly.

Once the sweaters are sewn together, they undergo a quality control inspection. Inspectors carefully examine each sweater for any defects or imperfections, ensuring that only the highest quality garments make it to the final stage of production. Any sweaters that do not meet the factory’s standards are set aside for rework or repair.

After passing inspection, the sweaters are sent to the finishing department. Here, they are steamed, pressed, and labeled before being packaged for shipping. The finishing touches are essential for ensuring that the sweaters look their best when they reach consumers.

Throughout the manufacturing process, the factory complex adheres to strict quality control measures to ensure that each sweater meets the highest standards. From design to production to finishing, every step is carefully monitored to guarantee that the final product is of the utmost quality.

| sweater factory | knit sweater manufacturer |

| sweater maker | knitwear men blanks manufacturer |

| sweater producer | luxury sweaters Maker |

In conclusion, the manufacturing process of women’s sweaters in a factory complex is a complex and intricate process that requires skill, precision, and attention to detail. From sourcing materials to sewing panels together to finishing touches, each step plays a crucial role in creating high-quality garments that consumers love. The next time you slip on a cozy sweater, take a moment to appreciate the craftsmanship and dedication that went into creating it.