The Process of Manufacturing cardigans in Factories

Cardigans are a versatile and timeless piece of clothing that can be worn in a variety of settings. From cozy nights at home to professional meetings at the office, cardigans are a wardrobe staple for many people. But have you ever wondered how these beloved sweaters are made? In this article, we will take a closer look at the process of manufacturing cardigans in factories.

| joker sweater manufacturer | baby sweater onesie Maker |

| hirka kazak Producer | parada erkek kazak manufacturer |

| tricot dresses Maker | men’s jacket sweater manufacturer |

| embroidered sweaters Producer | sweater customize manufacturer |

| knitwearvelvet Producer | cinch pullover maker |

| factory custom Producer | sweater hoodie anak Producer |

| fringe sweater maker | teddy fleece jumper Maker |

| jumper for Producer | sweaters knitted manufacturer |

The first step in the manufacturing process is designing the cardigan. This involves creating a pattern that will be used to cut the fabric and assemble the sweater. Designers work closely with manufacturers to ensure that the final product meets their vision. Once the design is finalized, the next step is selecting the materials.

Quality materials are essential for creating a durable and comfortable cardigan. Manufacturers carefully choose the type of yarn and fabric that will be used in the production process. This decision is crucial, as it will determine the overall look and feel of the finished product. Once the materials are selected, the manufacturing process can begin.

The first stage of production is cutting the fabric. Large sheets of fabric are laid out and the pattern is carefully placed on top. Workers use cutting machines to precisely cut out the pieces that will be used to construct the cardigan. This step requires precision and attention to detail to ensure that each piece is cut accurately.

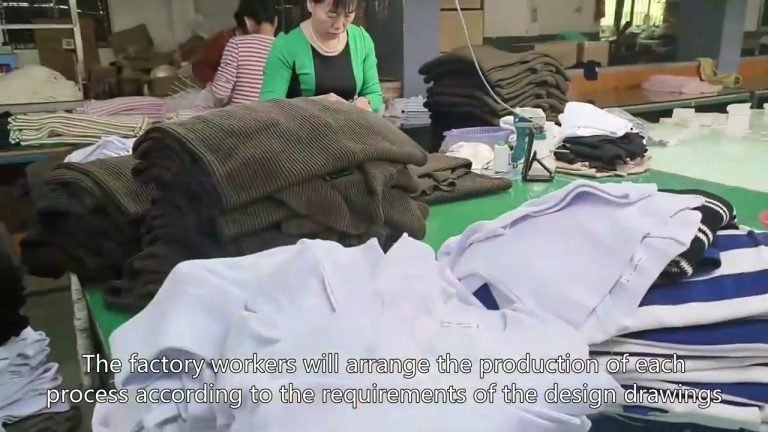

After the fabric pieces are cut, they are sewn together to create the body of the cardigan. Skilled seamstresses work diligently to stitch the pieces together, paying close attention to the seams and ensuring that the sweater is constructed properly. Once the body of the cardigan is complete, the next step is adding the finishing touches.

Finishing touches such as buttons, zippers, and pockets are added to the cardigan to give it a polished look. These details are carefully selected to complement the design of the sweater and enhance its overall appearance. Once all the finishing touches are in place, the cardigan is inspected for quality control.

Quality control is an essential part of the manufacturing process. Inspectors carefully examine each cardigan to ensure that it meets the standards set by the manufacturer. Any defects or imperfections are noted and the sweater is either repaired or discarded. This step is crucial in ensuring that only high-quality cardigans make it to the market.

Once the cardigans have passed quality control, they are packaged and prepared for shipment. Manufacturers work with distributors and retailers to get the sweaters to customers around the world. From cozy cable-knit designs to sleek and modern styles, cardigans are a popular choice for people of all ages.

In conclusion, the process of manufacturing cardigans in factories is a complex and detailed one. From designing the pattern to selecting materials and adding finishing touches, each step requires skill and precision. The end result is a high-quality sweater that is sure to become a wardrobe favorite. So next time you slip on your favorite cardigan, take a moment to appreciate the craftsmanship that went into creating it.