The Process of aran sweater manufacturing

The process of Aran sweater manufacturing is a fascinating one that involves skilled craftsmanship and attention to detail. Aran sweaters are known for their intricate patterns and high-quality materials, making them a popular choice for those seeking warmth and style. In this article, we will explore the various steps involved in the manufacturing of Aran sweaters, from sourcing the materials to the final product. The first step in Aran sweater manufacturing is sourcing the materials. Aran sweaters are typically made from merino wool, a soft and luxurious material known for its warmth and durability. Manufacturers often work with merino wool sweater manufacturers in lahore, a city renowned for its textile industry. These manufacturers provide the high-quality merino wool needed to create the finest Aran sweaters.

Once the materials are sourced, the next step is the knitting process. Knitting is a skill that requires precision and expertise. Knitting machines are used to create the intricate patterns that are characteristic of Aran sweaters. Skilled knitters carefully program the machines to produce the desired patterns, ensuring that each stitch is perfect. This step requires a keen eye for detail and a steady hand.

After the knitting process is complete, the next step is blocking. Blocking is a crucial step in the manufacturing process as it helps to shape the sweater and ensure that it fits properly. The sweater is carefully stretched and pinned onto a blocking board, allowing it to dry in the desired shape. This step is essential for achieving the perfect fit and shape of an Aran sweater.

Once the sweater is blocked and dried, it is time for the finishing touches. This includes sewing on buttons, attaching labels, and inspecting the sweater for any imperfections. Skilled seamstresses carefully sew on buttons, ensuring that they are securely attached. Labels are also added, indicating the brand and care instructions for the sweater. Finally, the sweater undergoes a thorough inspection to ensure that it meets the high standards of quality that Aran sweaters are known for.

The first step in Aran sweater manufacturing is sourcing the materials. Aran sweaters are typically made from merino wool, a soft and luxurious material known for its warmth and durability. Manufacturers often work with merino wool sweater manufacturers in lahore, a city renowned for its textile industry. These manufacturers provide the high-quality merino wool needed to create the finest Aran sweaters.

Once the materials are sourced, the next step is the knitting process. Knitting is a skill that requires precision and expertise. Knitting machines are used to create the intricate patterns that are characteristic of Aran sweaters. Skilled knitters carefully program the machines to produce the desired patterns, ensuring that each stitch is perfect. This step requires a keen eye for detail and a steady hand.

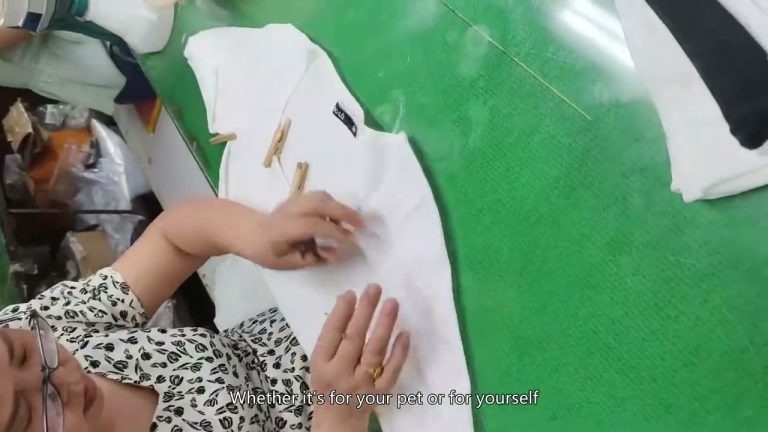

After the knitting process is complete, the next step is blocking. Blocking is a crucial step in the manufacturing process as it helps to shape the sweater and ensure that it fits properly. The sweater is carefully stretched and pinned onto a blocking board, allowing it to dry in the desired shape. This step is essential for achieving the perfect fit and shape of an Aran sweater.

Once the sweater is blocked and dried, it is time for the finishing touches. This includes sewing on buttons, attaching labels, and inspecting the sweater for any imperfections. Skilled seamstresses carefully sew on buttons, ensuring that they are securely attached. Labels are also added, indicating the brand and care instructions for the sweater. Finally, the sweater undergoes a thorough inspection to ensure that it meets the high standards of quality that Aran sweaters are known for.

In conclusion, the process of Aran sweater manufacturing is a meticulous one that involves sourcing high-quality materials, skilled knitting, blocking, adding finishing touches, and packaging. Each step requires expertise and attention to detail to create the beautiful and luxurious Aran sweaters that are loved by many. From the sourcing of merino wool to the final packaging and shipping, every aspect of the manufacturing process is carefully executed to ensure the highest quality. So, the next time you put on an Aran sweater, take a moment to appreciate the craftsmanship and dedication that went into creating it.