Understanding knitwear manufacturing terminology

Knitwear manufacturing terminology can be quite confusing for those who are not familiar with the industry. From understanding the different types of stitches to knowing the various techniques used in cardigan manufacturing, it is essential to have a basic understanding of the terminology to navigate the world of knitwear manufacturing. One of the first terms to know is “stitch.” In knitting, a stitch refers to a loop of yarn that is pulled through another loop to create a fabric. There are several types of stitches, including the basic knit stitch and purl stitch. These stitches are the building blocks of knitwear and are used to create various patterns and textures.Another important term is “gauge.” Gauge refers to the number of stitches and rows per inch in a knitted fabric. It is crucial to achieve the correct gauge when knitting a garment to ensure that it fits properly. Knitting with a different gauge can result in a garment that is too small or too large.

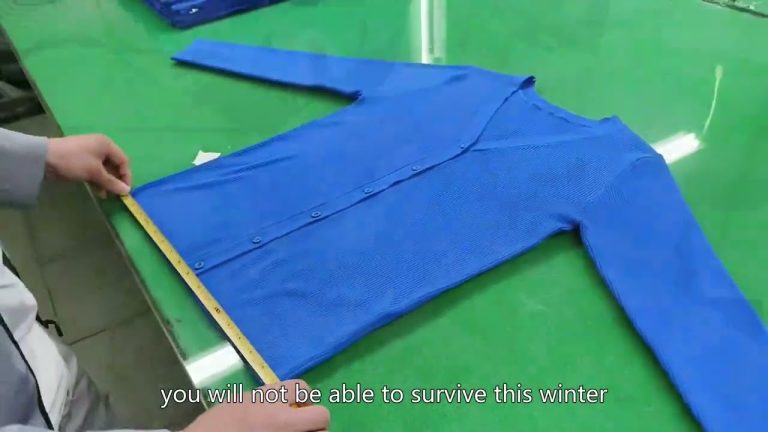

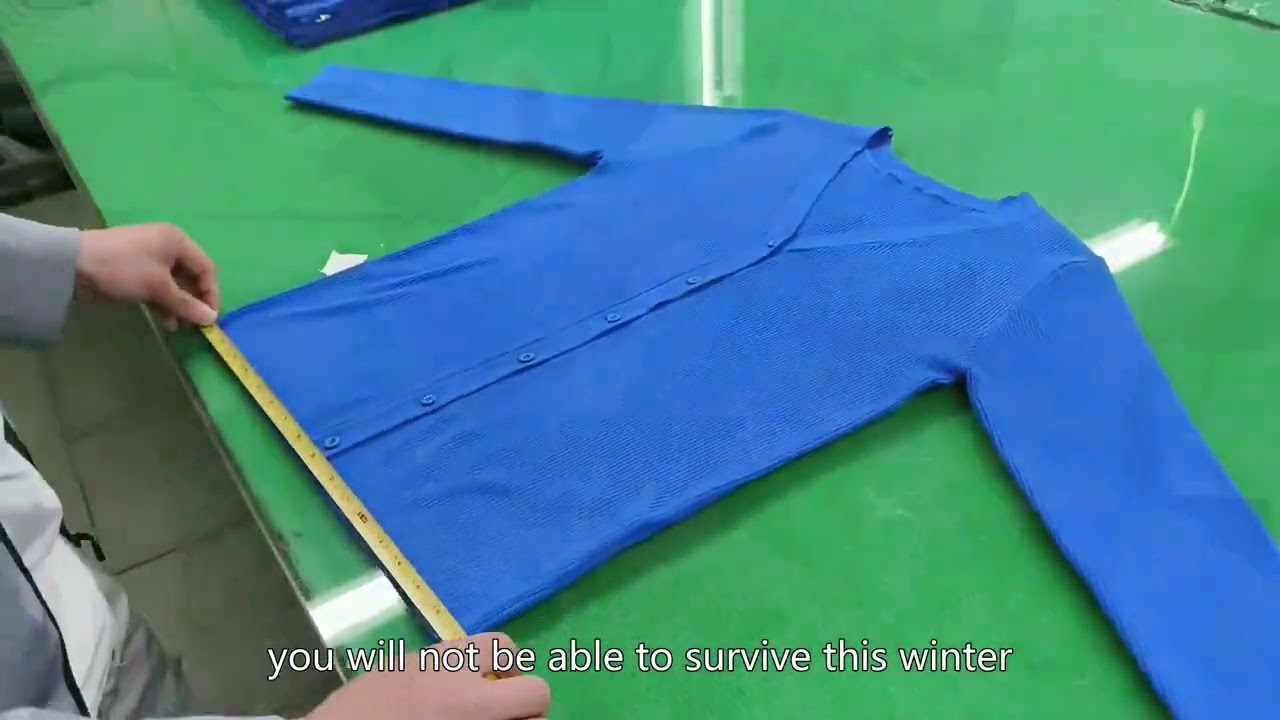

When it comes to cardigan manufacturing, there are several techniques that are commonly used. One of these techniques is “seaming.” Seaming involves joining different pieces of knitted fabric together using a needle and yarn. This technique is used to create the structure of the cardigan, such as attaching the sleeves to the body.

Another technique used in cardigan manufacturing is “blocking.” Blocking is the process of shaping and stretching the knitted fabric to achieve the desired dimensions and drape. This is typically done by wetting the garment and then pinning it into shape. Blocking helps to even out the stitches and give the cardigan a professional finish.

In addition to stitches and techniques, there are also various types of yarn used in knitwear manufacturing. One common type is “merino wool.” Merino wool is known for its softness and warmth, making it a popular choice for cardigans. Other types of yarn include cotton, acrylic, and cashmere, each with its own unique properties and characteristics.

Understanding knitwear manufacturing terminology is not only important for those working in the industry but also for consumers. Knowing the different stitches, techniques, and types of yarn can help consumers make informed decisions when purchasing knitwear. It allows them to understand the quality and craftsmanship that goes into each garment.

In addition to stitches and techniques, there are also various types of yarn used in knitwear manufacturing. One common type is “merino wool.” Merino wool is known for its softness and warmth, making it a popular choice for cardigans. Other types of yarn include cotton, acrylic, and cashmere, each with its own unique properties and characteristics.

Understanding knitwear manufacturing terminology is not only important for those working in the industry but also for consumers. Knowing the different stitches, techniques, and types of yarn can help consumers make informed decisions when purchasing knitwear. It allows them to understand the quality and craftsmanship that goes into each garment.